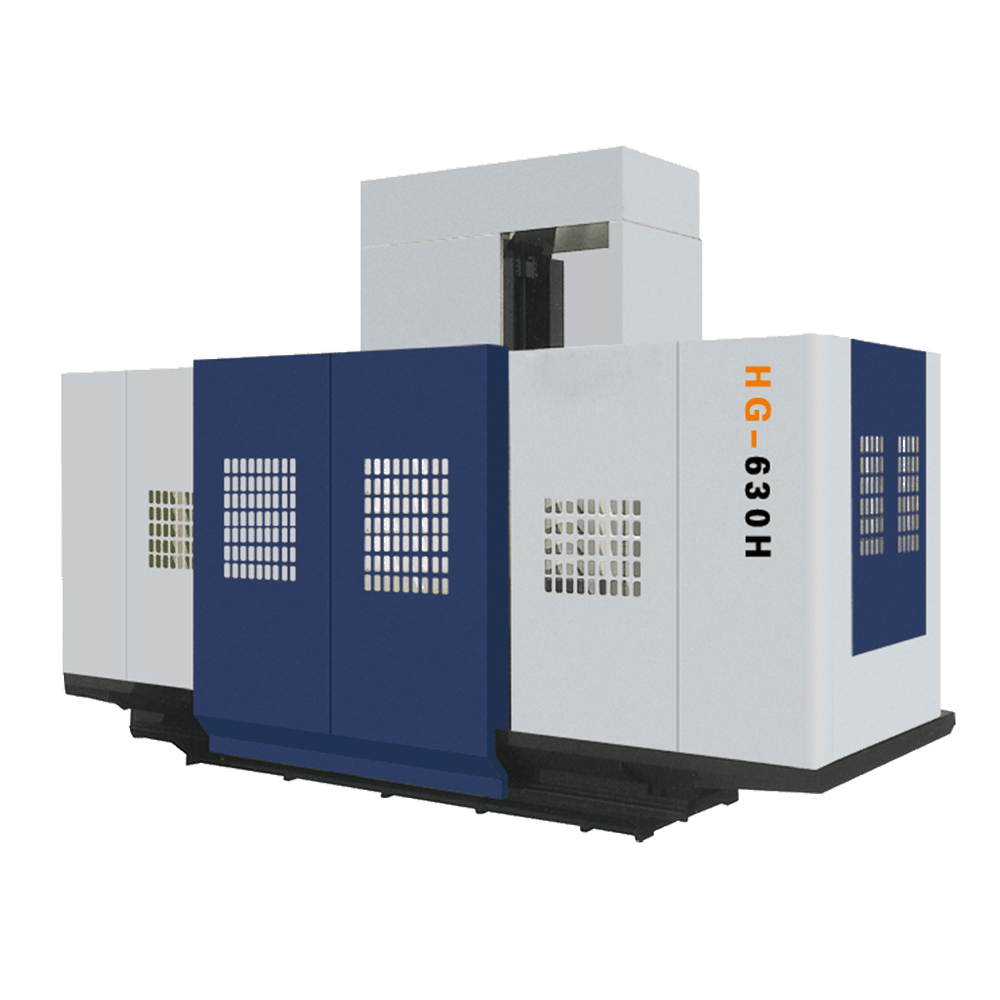

What is Horizontal Machining Center

HG Machinetools Horizontal Machining Center is a drilling and milling machine where the main spindle is mounted on a horizontal axis in relation to the work table. Horizontal machining is used for mass production of metal components in all kinds of industries.